Hydrogen-based Direct Reduction of Iron Oxide with Dr. Leili Tafaghodi, McMaster University

ASM Speaker Series In-person Event of our Brian Ives Lectureship Award Winner

March 26th 2026 (6:30pm EST) – Holiday Inn 590 Argus Rd, Oakville, ON L6J 3J3 (near Oakville GO station)

About the talk:

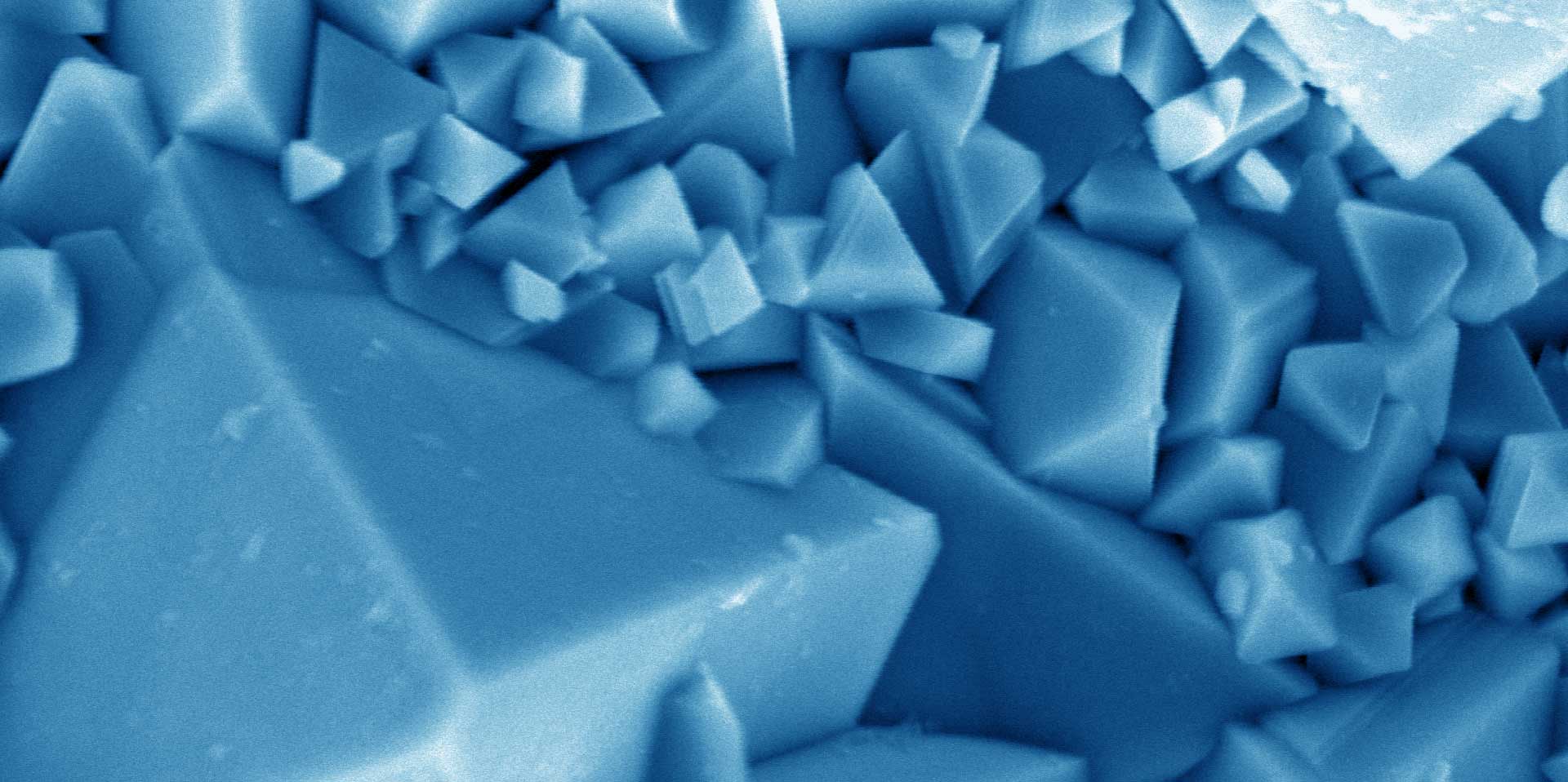

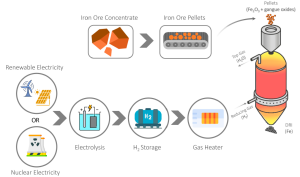

Despite numerous studies on hydrogen-based direct reduction of iron ore, a comprehensive understanding of the reduction kinetics remains a challenge. This difficulty stems from the complex interplay of various factors across multiple length scales. One of the main challenges is the limited understanding of the influence of the evolving microstructure of iron ore during the reduction process. The intricate microstructural changes, including the formation of pores, cracks, and different iron oxide phases, create a dynamic system that is challenging to characterize and model.

Most previous research in this field has focused on analyzing kinetics through thermogravimetric experiments, with only limited microstructural observations that were confined to the post-reduction state. While thermogravimetry offers a valuable tool for investigating the reduction kinetics of iron ore, relying solely on its curves for analysis presents several drawbacks. These drawbacks primarily arise from the complex, multi-scale nature of the reduction process, which involves an interplay of chemical, physical, and mechanical phenomena. To overcome these limitations, a multi-scale characterization approach is crucial for a comprehensive understanding of reduction kinetics. Combining thermogravimetry with techniques such as electron/ X-ray microscopy allows for a detailed analysis of microstructure evolution, chemical composition, and defect distribution during reduction. These insights provide a more accurate interpretation of the kinetic data and enable a deeper understanding of the underlying reduction mechanisms.

The research at McMaster University on hydrogen-based direct reduction of iron ore pellets concentrates on understanding the detailed microstructural changes during the reduction process and their relationship with reduction kinetics. The experiments span temperatures from 700 to 1000°C and include several interrupted reductions at each temperature point. The study not only examines DR-grade iron ore pellets but also investigates BF-grade pellets, which contain higher silica content. This line of research is increasingly relevant as the shift towards hydrogen direct reduction processes elevates the demand for DR-grade pellets. Initial results from these experiments are promising; however, the influence of high impurity levels, particularly silica, on the reduction mechanisms and the structural integrity of the pellets remains to be fully understood. The first proposed research topic involves examining this phenomenon in detail through the use of Electron backscatter diffraction (EBSD) and correlative X-ray computed tomography (XCT).

Want to learn more? Register below to join us on Mar 26th with Leili!

About The Speaker

Dr. Leili Tafaghodi

Professor Tafaghodi’s research program has significantly advanced the critical fields of sustainable extractive metallurgy and waste management in the metals industry, both of which are integral to the UN’s sustainable development goals. This program has garnered national and international recognition through the acquisition of competitive research grants, collaborations with global industries and national agencies, publications in high-impact journals, and invitations to deliver lectures at international institutions and conferences.

As the leader of the Process Metallurgy research group at McMaster University, Professor Tafaghodi has supervised and co-supervised 19 researchers, ranging from undergraduate students to PhD students and postdoctoral fellows exploring sustainable metal production and refining methods that maximize resource utilization while minimizing waste generation and energy consumption. By creating a dynamic and responsive training environment, offering collaboration opportunities with multinational companies and governmental agencies, and fostering a comprehensive understanding and commitment to inclusivity, Professor Tafaghodi has empowered her students to achieve remarkable success. They have published over 40 academic papers and conference proceedings, received several prestigious student awards, and secured positions in academia and industry, reflecting their outstanding academic performance and research contributions.

Dr. Tafaghodi started her research career at Sharif University of Technology and moved to the University of Toronto for her graduate studies where she completed her PhD research on thermodynamics of silicon refining. Prior to joining McMaster, she was an Assistant Professor and the Extractive Metallurgy Industry Chair at the University of British Columbia.